At first, the waiting feels fine, full of excitement. Because a finished manuscript is a kind of relief, like setting down a heavy bag after a long walk. But then the calendar starts to speak. It speaks in quiet numbers: two days, ten days, three weeks, six weeks. It speaks in the small, stubborn ways.

The strange truth is that the most physical part of publishing, the part that ends with a book you can hold, often begins with nothing more than a file and a promise. A PDF. A cover image. A few boxes were checked in an online portal. After that, time takes over. It is not the time of inspiration. It is manufacturing time. It is the time of machines and people and schedules, of checks and rechecks, of binding and trimming and packing.

This blog focuses on a common question authors often forget to ask early like how long book printing actually takes. It matters because work that isn’t ready or visible doesn’t bring any results. The stakes are always high, especially if you have put in all the hard work and you have a deadline to deliver. It could be your launch event, media windows, school visits, or book festivals.

The modern print landscape has split into two strong paths:

#1 Fast print-on-demand systems that can produce single copies quickly

#2 Slower offset runs built for volume and unit cost. The choice is not only about printing cost or quality. It is about the kind of clock a writer is willing to live with.

And there’s a second promise here. Along the way, the article will teach a writing technique that can make any complex process, including printing, read like a story because time is not just a production issue. Time is also a narrative tool.

How Long Does It Take to Print a Book? A Timeline That Starts Before the Press

When people ask, what is the time needed to print a book? they often mean the moment after the manuscript is “done.” But printing rarely begins the day the last sentence is typed. Even if the text is finished, the book may not be print-ready. That phrase print-ready sounds simple. It isn’t. It includes design, file setup, proofing, and decisions that can either speed the job or slow it down.

A useful way to think about book printing is to picture a narrow hallway with several doors. The book has to pass through each one. If it sticks at any door, the whole timeline stretches.

The doors usually look like this:

- Prepress and file checks (Are the files correct? Are fonts embedded? Are margins safe? Is the spine width right?)

- Proofing (Digital proof, sometimes a physical proof, sometimes multiple rounds)

- Printing (The pages are produced digitally for POD, or on large offset presses for big runs)

- Binding and finishing (Trimming, gluing, stitching, casing-in, jacket wrapping, foil stamping, lamination)

- Quality control and packing (Counting, boxing, labeling, pallets for freight)

- Shipping and receiving (Carrier pickup, transit, customs if overseas, delivery appointments)

Most first-time authors expect one clean block of time labeled “printing.” But the calendar is more like a chain, and each link has its own risks. A single wrong barcode on a cover can cost a week. A last-minute change to the spine can trigger a full file reapproval. A proof that comes back with a color shift can restart decisions you thought were settled.

So the honest answer is: printing is a process with stages, and the total time depends on the choices made long before the first page is pressed.

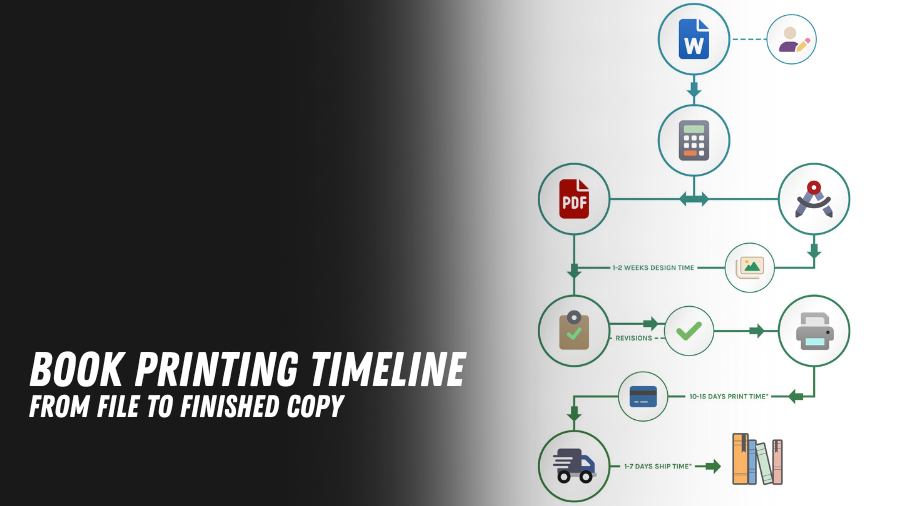

Book Printing Timeline: From File to Finished Copy

A clear book printing timeline does not make delays disappear, but it does make them legible. It lets an author plan like an adult instead of hoping like a child. Below is a practical timeline framework, one that matches how printers and production managers tend to think.

Book Printing Turnaround Time and the Prepress Gate

The first stage is prepress, which is the printer’s way of asking: “Can we safely run this?” Even when a book looks perfect on a laptop, a printer may flag issues that only show up in production, images too low-resolution, blacks that will muddy on press, bleeds that are missing, margins too tight for trimming.

For many projects, prepress can be quick often a day or two if the files are standard and the author has used a professional template. It can also stretch longer if the files need repair, if the cover spine needs recalculation, or if the book has unusual specs (foldouts, heavy ink coverage, special papers, or complex finishes).

This is one reason authors sometimes feel the printer is “slow” when the printer is actually being cautious. A good printer protects the book from an expensive mistake.

Proofing: The Week That Saves the Month

Proofing is where the book becomes real enough to argue with. A proof can reveal that the cover type is too thin, the spine text is off-center, or the interior has a quiet error that survived every edit. Proofing can be fast if the author approves quickly. It can also drag if the author is uncertain or if the team keeps revising.

A useful rule: each proof round adds time, but it also buys safety. The author has to decide what kind of risk they can tolerate.

How Long Does Book Binding Take?

People rarely ask how long does book binding take until they learn that binding is not a simple “after” step.

All in all, binding is said to be a craft that defines the look and feel of your book, from visualizing how it opens to how it lies on a table or survives in a backpack.

The time to do the binding depends on the type of binding the book requires:

- Perfect binding, also known as softcover binding, is a popular choice for paperbacks. In this type of binding, the pages are gathered with the help of glue, the cover is wrapped, the spine edge is roughened, and then the book is trimmed.

- Case binding is common for hardcovers. In this, the text block is made, then attached to a rigid case. There may be endpapers, headbands, a ribbon, and a jacket to ensure the durability of the book.

- Smyth-sewn binding is a sturdier option for authors. Signatures are sewn together before being bound in a book for authors. This can add time, but it improves durability and how the book opens.

Binding can be a quick part of a smooth run, or it can become the bottleneck, especially for hardcovers, specialty finishes, or books that require extra curing time for glue and laminates.

The Hidden Stage: Packing, Labeling, and “Ready to Ship”

The last production stage often surprises people because it feels so basic. But boxing and labeling are not trivial when there are hundreds or thousands of copies. Errors here can cause lost shipments, wrong destinations, or damaged corners. Good packing takes time. It is also the difference between books arriving crisp and books arriving embarrassed.

Printing a Book Time Frame: The Variables That Stretch or Shrink the Calendar

A printing a book time frame is not only a matter of “fast printer” versus “slow printer.” The biggest drivers are usually choices. Some are obvious, some are not.

Quantity is the clearest variable. One copy and one thousand copies do not move through the same system. One copy is often a digital job. One thousand copies may be offset, may require paper ordering, and may require scheduling around other large runs.

Trim size and page count also matter. A book with an unusual size might require a nonstandard setup. A thick book needs a wider spine, heavier handling, and sometimes slower binding speeds.

Color interiors can add time, especially if the printer needs to calibrate color, run tests, or switch inks. Even when the press run is quick, the approvals can slow.

Special finishes foil stamping, embossing, spot UV, deckled edges, colored endpapers, often add steps. Each step is a place where production can pause.

Seasonality is real. Around major retail seasons, many printers book up. A printer with a full queue may not be able to start immediately, no matter how ready the files are.

When an author asks, “Why is my timeline longer than I thought?” the answer is usually here. The book is not only text. It is an object, and objects have physics.

How Long to Print a Book When the Plan Is Simple?

Some books are designed to move cleanly through the system: black-and-white interior, standard trim size, common paper stock, paperback format, no special finishes. For these, how long to print a book can be refreshingly predictable.

In a straightforward case, a typical pattern might look like:

- File check and proof approval: several days to a couple of weeks, depending on the speed of response

- Printing and binding: days to a couple of weeks, depending on method and queue

- Packing and shipping: days to weeks, depending on distance and carrier

But even “simple” has a catch: the author’s own decision time. A printer can run quickly. An author can take ten days to approve a proof. The calendar does not care who caused the delay. It only counts.

How Long Does It Take to Print a Paperback Book?

When people picture a printed book, they often picture a paperback first, flexible cover, clean spine, the kind of book that can be tossed in a bag. So it makes sense that a common question is how long does it take to print a paperback book?

For paperbacks, the big split is between print-on-demand and offset.

A paperback produced through a print-on-demand workflow is often fast to manufacture once files are approved, sometimes within days. But speed is not the same as certainty. POD systems can fluctuate based on plant capacity, location, and shipping method. A single copy might print quickly, while a larger batch might be routed to a different facility with a different queue.

Offset paperbacks often used for larger quantities,usually take longer because they involve press scheduling, paper ordering, plate setup, and longer finishing runs. The trade-off is cost per unit and, in some cases, more control over paper choices and consistency.

A paperback can be the “quick” format, but it still carries the full chain: prepress, proof, print, bind, pack, ship. The timeline is only as fast as the slowest link.

How Long Does It Take to Print a Hardcover Book?

Hardcovers have their own aura. They look serious on a shelf. They feel like a commitment. They also take more time. So the question of how long does it take to print a hardcover book is partly about admiration and partly about fear.

A hardcover is not just “a paperback with a thicker cover.” It is a different build. The case must be made. The text block must be attached. If there is a dust jacket, it must be printed, finished, and wrapped. If there is foil stamping or embossing, that is another stage.

Hardcovers also tend to invite higher expectations. People notice crooked jackets. They notice dull foil. They notice a casewrap seam that doesn’t line up. The more the book asks the reader to pay attention, the more the production team has to slow down and check.

This does not mean hardcovers are always slow. It means they have more ways to become slow. A clean, standard hardcover can move well. A complex hardcover, special materials, heavy pages, unique finishes can require more time in both setup and finishing.

In planning terms, hardcover timelines often need more slack. Not because printers are careless, but because hardcovers contain more moments where craftsmanship matters.

Print on Demand Book Printing Timeline

The modern miracle of publishing is that a book can be printed one copy at a time, close to where it will be shipped, without a warehouse. That is the appeal of print on demand book printing time: it feels like a shortcut around the old world.

POD can be fast because it is built on digital presses and automated binding lines. Once the files are accepted, the system can produce copies as orders come in. For many authors, this removes the stress of ordering too many books and storing them in a garage.

But POD has its own truth: the author trades some control for convenience. Paper options may be limited. Color can vary slightly from run to run. If demand spikes, orders may be routed to different plants. The timeline may be short, but it can also be uneven.

POD is best understood as a service system, not a single press in a single building. The question is not only “How quickly can a book be printed?” but “where is it printing today, and how busy is that plant?”

For authors who need books for a specific event, POD can work well if planned early and tested with sample orders. It can also create panic if the author assumes every order will arrive in the same predictable window.

Offset Book Printing Turnaround Time

If POD is the fast lane, offset is the long route with better scenery. Offset book printing turnaround time is usually longer, but it is built for volume and often for consistency.

Offset printing involves making plates, running large sheets, and using finishing equipment that is optimized for thousands of copies. It can allow more choices: paper stocks, coatings, special finishes, and tighter control over how a large run looks from the first copy to the last.

Offset also tends to require more upfront planning. Paper may need to be ordered. The press schedule may be set weeks in advance. If the printer is managing many projects, your book becomes a line item on a complex calendar.

In exchange, offset can deliver a large shipment that arrives like a single event: pallets of books, uniform and ready for distribution. For authors with bulk needs schools, organizations, conferences, preorders shipping from a central point, this can be worth the longer lead time.

Offset rewards patience, but it also punishes poor planning. A last-minute cover change can be costly. A delayed proof approval can push the job into a later press slot. Offset does not like surprises.

POD vs Offset Printing Timeline: Choosing the Clock That Fits the Book

The POD vs offset printing timeline is not a simple contest. It is a question of what the author values most: speed, cost per unit, control, or certainty at scale.

POD often offers:

- Faster manufacturing for small quantities

- Less need for storage

- Easier reprints (because the “reprint” is just more orders)

Offset often offers:

- Better economics at higher quantities

- More options for materials and finishes

- A single, coordinated delivery for large runs

But the bigger difference is emotional. POD can feel like the book is always available, always on call. Offset can feel like a commitment with a countdown.

An author deciding between them should ask a plain question: “What failure would hurt more?”

- If the worst failure is running out of books at a live event, an offset (or an early bulk order) may be safer.

- If the worst failure is ordering too many books and paying for storage, POD may be safer.

The timeline is not only time. It is risk management in calendar form.

How Long Does It Take to Print 100 Copies of a Book?

The question about printing 100 book copies is very specific, and that’s helpful. It pushes the author to think practically, like a producer, instead of just dreaming.

One hundred copies sit in the middle zone. It is small enough that many digital printers can handle it quickly. It is large enough that some POD systems may treat it differently from a single retail order, especially if the copies need to ship together to one address.

In many cases, 100 copies can be produced relatively fast once files are approved, often within days to a couple of weeks depending on printer capacity, whether the book is paperback or hardcover, and whether the interior is color.

But here’s the part authors often miss: the clock includes more than printing. It includes time for:

- reviewing and approving a proof

- fixing any file issues

- choosing shipping speed and destination

- receiving and inspecting the books

- handling damage replacements if needed

One hundred copies is also the quantity where an author starts to feel the difference between “a book” and “inventory.” Boxes show up. The hallway fills. The book stops being a file and becomes a physical presence that needs a plan. If an author wants 100 copies for a launch, the safest approach is to treat the order like a small production run, not like a casual purchase.

Book Printing Turnaround Time Is a Story: The Writing Technique That Makes Process Readable

Most how-to articles about printing read like manuals. They list steps. They give ranges. They are useful, but they rarely stay in the mind. A reader finishes them with information, not clarity.

Here is a technique that can change that, one that works for essays, features, memoirs, even business writing. Call it The Clock-Scene Method. It turns a process into a narrative by using time as structure, not decoration.

The method is simple: instead of explaining the whole process at once, the writer selects a few “time-stamped scenes” that reveal the stakes. Time is not just a measurement. It is pressure. It is a choice.

Step 1: Build a Real Timeline Before Writing the First Sentence

A writer cannot narrate time if they have not mapped it. On a page, list the stages of the process in order. Then add realistic ranges. Do not aim for perfect accuracy. Aim for a believable map.

For a printing story, the map might include: file check → proof → changes → approval → print → bind → pack → ship → receive.

This map becomes a spine. Not a metaphorical spine. A structural spine.

Step 2: Choose Three Moments Where the Clock Tightens

Every process has moments when the outcome can change. In printing, these moments often include:

- the proof arrives and looks wrong

- the author notices a typo after approval

- a shipment date collides with a launch date

Pick three. Make them concrete. Give them a day on the calendar. You do not need to invent drama. The process provides it.

Step 3: Write Each Moment as a Small Scene, Not a Summary

A scene has sensory detail and a decision. It shows someone noticing something and choosing what to do. Even in a practical article, a scene keeps the reader oriented.

Instead of: “Proofing can take time.”

Try: “On a Tuesday morning, the proof lands in the inbox. The cover looks darker than it did on screen. The author stares at the blue shadow along the title and wonders if anyone else will notice. Then the clock does what clocks do: it keeps going.”

This is not fiction. It is a way of making the reader feel the reality of the choice.

Step 4: Use Time Words Like Anchors

Good process writing uses time words the way good reporting uses place names. It keeps the reader from floating away.

Useful anchors include: “two days later,” “by Friday,” “the next morning,” “in the third week,” “the night before approval.”

These phrases do not clutter the prose. They clarify it.

Step 5: End With the Reader’s Calendar, Not the Writer’s Wisdom

The point of teaching is not to sound smart. The point is to leave the reader able to act. So the final paragraph of a process story should translate into a plan: what to do, when to do it, what to avoid. With this information, you can create a realistic schedule, avoid delays, and launch your book with confidence.

The Clock-Scene Method does one more thing, quietly. It respects the reader’s attention. It does not ask them to memorize. It helps them picture. And what people can picture, they can plan for.

Planning the Launch: Using the Book Printing Timeline Like a Safety Net

Launch planning is where timelines become emotional. It is not just logistics. It is pride and vulnerability. Nobody wants to stand at a table with an empty display.

The safest launch plan treats printing as one part of a larger chain:

- editing and design

- proofing and approvals

- printing and binding

- shipping and receiving

- contingency time for problems

A calm strategy is to schedule backward from the moment the books must be in hand. Not the launch date on social media, the date the author needs the books physically. Then add slack at each stage. Slack is not laziness. Slack is respect for reality.

A practical mindset is to assume that something will require attention: a proof that needs a tweak, a carton delayed, a box with damaged corners. If everything goes perfectly, the slack becomes breathing room. If something goes wrong, the slack becomes rescue time.

In other words, the author does not need optimism. The author needs a margin.

Book Printing Turnaround Time and the Art of a Well-Timed Launch

Ultimately, the time it takes to print a book reflects whether the writer wants to move fast or stay patient. Printing a book isn’t romantic, but it’s a personal process involving paper, glue, and ink. And once time is spent, it can’t be taken back.

For authors who want their work to arrive with dignity, the best move is to treat the calendar as part of the craft. And if that calendar feels hard to build alone, Arkham House Publishers offers affordable book printing solutions that can help authors map realistic production schedules, choose the right printing path, and get books in hand when the moment finally comes.